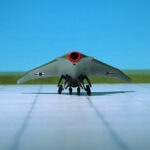

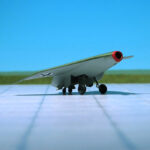

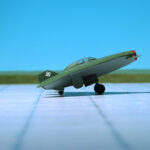

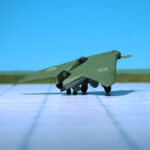

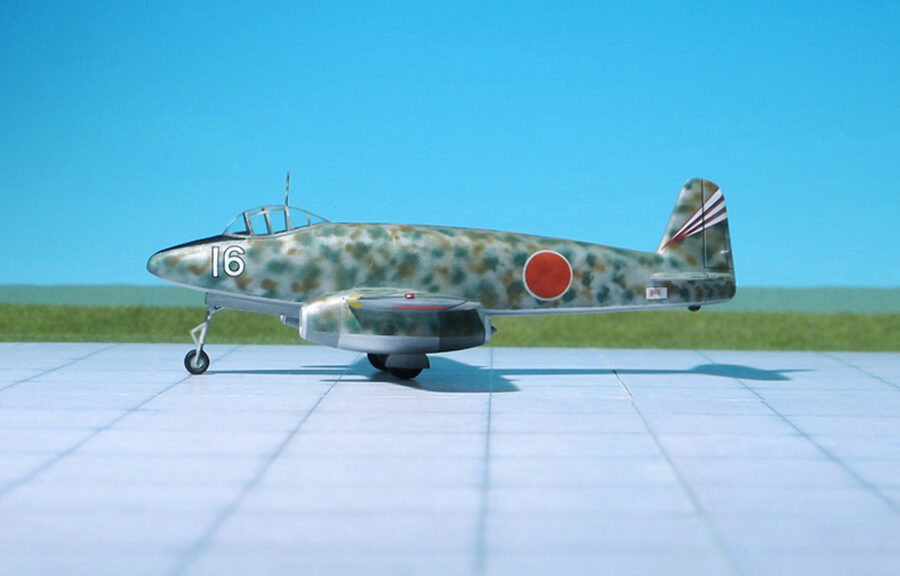

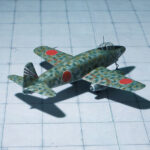

TYPE: Ground attack aircraft

ACCOMMODATION: Crew of two

POWER PLANT: One Mikulin AM-38F liquid-cooled engine, rated at 1,720 hp

COMMENT: The Ilyushin Il-2 „Shturmovik“ was a ground attack aircraft produced by the Soviet Union in large numbers during WW II. To Il-2 pilots, the aircraft was simply the diminutive “Ilyusha”, to the soldiers on the ground, it was the “Hunchback”, the “Flying Tank” or the “Flying Infantryman”. With 36,183 units produced during the war it was the most built aircraft forever.

The idea for a Soviet armored ground-attack aircraft dates to the early 1930s. The Il-2 was designed by Sergey Ilyushin and his team at the Central Design Bureau in 1938. Designated TsKB-55 it was a two-seat aircraft with an armoured shell weighing 700 kg, protecting crew, engine, radiators, and the fuel tank. Standing loaded, the Ilyushin weighed more than 4,700 kg making the armoured shell about 15% of the aircraft’s gross weight. Uniquely for a World War II attack aircraft, and similarly to the forward fuselage design of the World War I-era Imperial German Junkers J.I armored, all-metal biplane, the Il-2’s armor was designed as a load-bearing part of the Ilyushin’s monocoque structure, thus saving considerable weight. The prototype TsKB-55, which first flew on 2 October 1939, won the government competition against the Sukhoi Su-6 and received the VVS (Soviet Air Forces) designation BSh-2 (the BSh stood for “Bronirovani Shturmovik” or armoured ground attack). The prototypes – TsKB-55 and TskB-57 – were built at Moscow plant No 39, at that time the Ilyushin design bureau’s base.

The production aircraft passed State Acceptance Trials in March 1941, and was redesignated Il-2 in April. Deliveries to operational units commenced in May 1941.

The Il-2 was a single-engine, propeller-driven, low-wing monoplane of mixed construction with a crew of two (one in early versions), specially designed for assault operations. Its most notable feature was the inclusion of armor in an airframe load-bearing scheme. Armor plates replaced the frame and paneling throughout the nacelle and middle part of the fuselage, and an armored hull made of riveted homogeneous armor steel secured the aircraft’s engine, cockpit, water and oil radiators, and fuel tanks.

In early 1941, the Il-2 was ordered into production at four factories, but by the time Nazi Germany invaded the Soviet Union on 22 June 1941, only State Aviation Factory 18 at Voronezh and Factory 381 at Leningrad had commenced production, with 249 having been built by the time of the German attack.

Production early in the war was slow because after the German invasion the aircraft factories near Moscow and other major cities in western Russia had to be moved east of the Ural Mountains. Ilyushin and his engineers had time to reconsider production methods, and two months after the move Il-2s were again being produced.

As a result, “the production of Shturmoviks rapidly gained speed. Stalin’s notion of the Il-2 being ‘like bread’ to the Red Army took hold in Ilyushin’s aircraft plants and the army soon had their Shturmoviks available in quantity.”

The first use in action of the Il-2 was with the 4th ShAP (Ground Attack Regiment) over the Berezina River days after German invasion began. The aircraft was so new that the pilots had no training in flight characteristics or tactics, and the ground crew no training in servicing or re-arming. The training received enabled the pilots only to take-off and land; none of the pilots had fired the armament, let alone learned tactics. There were 249 Il-2s available on 22 June 1941. In the first three days, 4th ShAP had lost 10 Il-2s to enemy action, a further 19 were lost to other causes, and 20 pilots were killed. By 10 July, 4th ShAP was down to 10 aircraft from a strength of 65.

Tactics improved as Soviet aircrews became used to the Il-2’s strengths. Instead of a low horizontal straight approach at 50 metres altitude, the target was usually kept to the pilot’s left and a turn and shallow dive of 30 degrees was used, using an echeloned assault by four to twelve aircraft at a time. Although the Il-2’s RS-82 and RS-132 rockets could destroy armored vehicles with a single hit, they were so inaccurate that experienced Il-2 pilots mainly used the cannon.

The main problem with the Il-2 was the inaccuracy of its attacks. Towards the end of war, the Soviets were able to concentrate large numbers of Shturmoviks to support their main offensives. The effect, however, was often more psychological than actual physical destruction of targets, particularly against dug-in and armored targets. The heavy armor of the Il-2 also meant that it would typically carry only comparatively light bomb-loads, which together with the poor accuracy of its attacks made it a far less deadly attack aircraft than contemporary Allied fighter-bombers such as the Republic P-47 „Thunderbolt“ and Hawker „Typhoon“. The rocket projectiles especially were not effective, even the larger RS-132 (of which four were carried) having a warhead with only 0.9 kg of explosives, which compared poorly with the P-47’s typical load of ten 13 cm HVAR‘s, each having a 21 kg warhead, or the 8 to 12 27 kg warheads of the Hawker „Typhoon’s“ RP-3 rockets.

Heavy losses to enemy fighters forced the reintroduction of a rear gunner; early Il-2s were field modified by cutting a hole in the fuselage behind the cockpit for a gunner sitting on a canvas sling armed with a 12.7 mm UBT machine gun in an improvised mounting. The semi-turret gun mount allowed the machine gun to be fired at angles of up to 35° upwards, 35° to starboard and 15° to port. Tests showed that maximum speed decreased by between 10 and 20 km/h and that the two-seater was more difficult to handle because the center of gravity was shifted backwards. At the beginning of March 1942, a production two-seat Il-2 with the new gunner’s cockpit began manufacturer tests. The second cockpit and armament increased all-up weight by 170 kg so the flaps were allowed to be deployed at an angle of 17° to avoid an over-long takeoff run. The new variant had a lengthened fuselage compartment with an extended canopy offering some protection from the elements. Unlike the well-armoured cockpit of the pilot compartment with steel plating up to 12 mm thick behind, beneath and on both sides as well as up to 65 mm thick glass sections, the rear gunner was provided with 6 mm thick armour, effective only against rifle-calibre rounds.

While the Il-2 was a deadly air-to-ground weapon, and even a fairly effective interceptor against slow bombers and transport aircraft, heavy losses resulted from its vulnerability to fighter attack. Losses were very high, the highest of all types of Soviet aircraft, though given the numbers in service this is only to be expected. „Shturmovik“ losses (including Il-10 type), in 1941–1945, were of 10,762 aircraft. The main defensive tactic was flying low and power down as the fighters closed in to let the fighter overshoot and fly into the Il-2’s firing range (Ref.: 24).