TYPE: Interceptor aircraft, project

ACCOMMODATION: Pilot only

POWER PLANT: One Lorin type liquid fuel burning ramjet, power output unknown

PERFORMANCE: 750 mph (estimated)

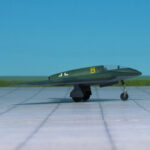

COMMENT: The Lippisch P.12, Lippisch P.13a and Lippisch P.13b were related design projects for a ramjet-powered delta wing interceptor aircraft studied in 1944 by German designer Alexander Lippisch. The P.12 and P.13a were unarmed, relying on reinforced wings to ram its opponent. All designs were to be powered by ramjets under development using liquid fuel or producer gas made in-flight from powdered coal. A full-seized test glider was built by students from technical universities of Darmstadt and Munich, designated DM-1 (Darmstadt-München 1) and flown to test low-speed aerodynamics. The design series were unrelated to the earlier Lippisch P.13 proposed by Messerschmitt’s Lippisch design office.

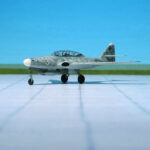

During 1942, while still working on the Messerschmitt Me 163 Komet (Comet) rocket fighter, Alexander Lippisch developed a sharply-swept, leaf-shaped delta wing which he believed was capable of supersonic flight. Out of this and subsequent development of the Lippisch P.11/Delta VI „power wing“ through 1943 and early 1944, he conceived the idea of a hollow delta wing (lifting body) with its interior shaped like a ramjet duct. As an interceptor fighter it would achieve supersonic speeds but would carry no armament. Instead it would be heavily reinforced and would ram its opponent. Initially conceived as a disposable machine with the pilot bailing out at the end of the mission, a landing skid was later added. Launch to ramjet operational speed would be via catapult, booster rockets, or launched by carrier aircraft.

The resulting design was initially assumed to use conventional liquid fuel and designated the P.12. But Lippisch had also become convinced of the benefits of solid fuel for short-duration high-speed flight and adopted this power source as the P.13. The design of both types then proceeded in parallel.

From autumn 1944, Alexander Lippisch had opened his own development office at the Aviation Research Institute Vienna (LFW) in Wiener Neustadt together with his mathematician from Messerschmitt Hermann Behrbohm on half-time (who still on half time worked for Messerschmitt in the underground facility of the Oberbayerische Forschungsanstalt in Oberammergau, Bavaria).

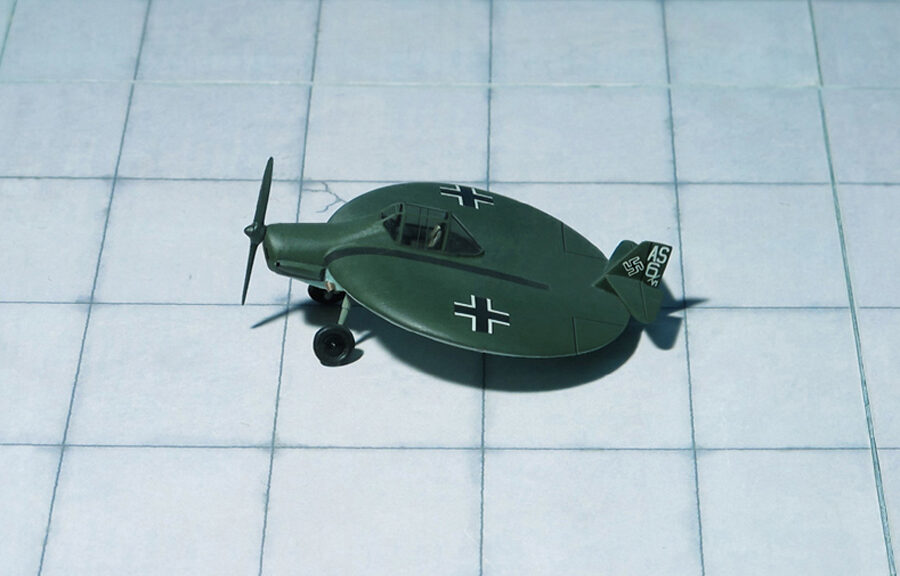

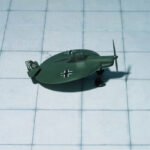

The P.12 was never fully defined but comprised studies of many variations. A model of it showed a typical configuration comprising a highly-swept delta flying wing. A large protruding oval shaped nose intake fed the single liquid fuel burning ramjet powerplant located between the delta wings. The wing centre section was hollow, with air ducts on either side of the cockpit leading to a large cavity which comprised the ramjet. The engine exhausted through a wide nozzle with control flaps above and below. Fuel tanks were located in the wing roots and fuselage. The pilot was seated in a finely blended cabin located above the ramjet combustion chamber. The delta wings were bent downward at the tips to form stabilizers for the single retracting central landing skid when on the ground. Wing area was approximately 130 ft2 and aspect ratio 1.33. A single triangular-shaped fin at the rear body was used as stabilizer.

For take-off the aircraft sat on a solid-fuel rocket-driven trolley or was towed by a tow-plane. It was envisaged that for test purposes the aircraft was placed on a superstructure on a carrier plane, probably a Dornier Do 217K. Finally, the Lippisch P.12 project was abandoned in favor of the P.13b (Ref.: 17).