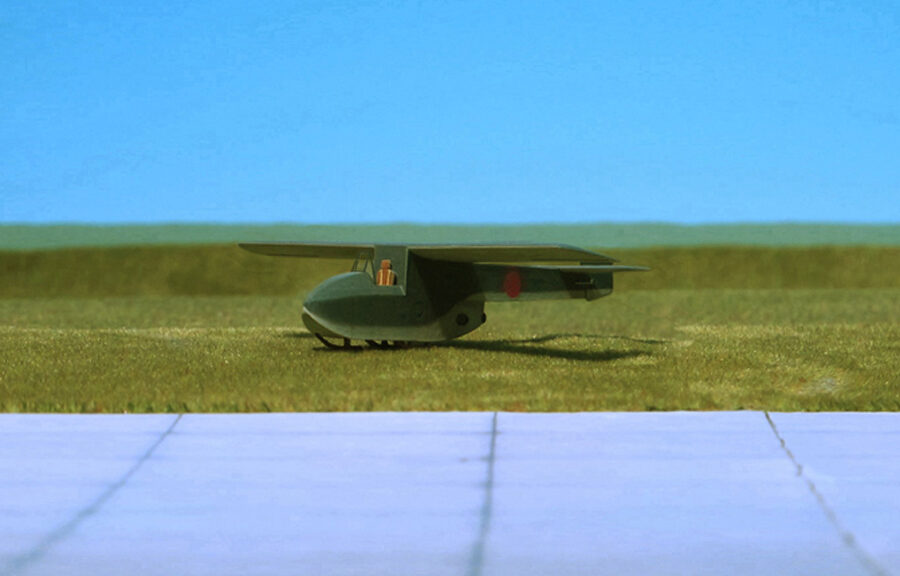

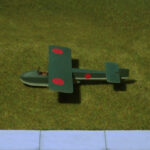

TYPE: High-altitude strategic bomber

ACCOMMODATION: Crew of 11

POWER PLANT: Four Wright R-3350-23 Duplex-Cyclone air-cooled turbocharged radial piston engines, 2,200 hp each

PERFORMANCE: 357 mp

COMMENT: The Boeing B-29 Superfortress was an American four-engined propeller-driven heavy bomber, designed by Boeing and flown primarily by the United States during World War II and the Korean War. Named in allusion to its predecessor, the Boeing B-17 Flying Fortress, the Superfortress was designed for high-altitude strategic bombing, but also excelled in low-altitude night incendiary bombing, and in dropping naval mines to blockade Japan. B-29s dropped the atomic bombs on Hiroshima and Nagasaki, the only aircraft ever to drop nuclear weapons in combat.

One of the largest aircraft of World War II, the B-29 was designed with state-of-the-art technology, which included a pressurized cabin, dual-wheeled tricycle landing gear, and an analog computer-controlled fire-control system that allowed one gunner and a fire-control officer to direct four remote machine gun turrets. The $3 billion cost of design and production, far exceeding the $1.9 billion cost of the Manhattan Project (development oft he atomic bomb), made the B-29 program the most expensive of the war. The B-29 remained in service in various roles throughout the 1950s, being retired in the early 1960s after 3,970 had been built.

Before World War II, the United States Army Air Force (USAAF) concluded that the Boeing B-17 Flying Fortress, which would be the Americans’ primary strategic bomber during the war, would be inadequate for the Pacific Theater, which required a bomber that could carry a larger payload more than 3,000 miles

In response, Boeing began work on pressurized long-range bombers in 1938. Boeing’s design study for the Model 334 was a pressurized derivative of the Boeing B-17 Flying Fortress with nosewheel undercarriage. Although the Air Corps lacked funds to pursue the design, Boeing continued development with its own funds as a private venture. In April 1939, Charles Lindberg convinced General Henry H. Arnold to produce a new bomber in large numbers to counter the Germans’ bomber production. In December 1939, the Air Corps issued a formal specification for a so-called “superbomber” that could deliver 20,000 lb of bombs to a target 2,667 mi away, and at a speed of 400 mph. Boeing’s previous private venture studies formed the starting point for its response to the Air Corps formal specification.

Boeing submitted its Model 345 on May 1940, in competition with designs from Consolidated Aircraft Model 33, which later became the Convair B-32 Dominator, Lockheed XB-30 and Douglas XB-31 Raidmaster. Douglas and Lockheed soon abandoned work on their projects, but Boeing received an order for two flying prototypes, which were given the designation XB-29, and an airframe for static testing on August 1940, with the order being revised to add a third flying aircraft on December. Consolidated continued to work on its Model 33, as it was seen by the Air Corps as a backup if there were problems with Boeing’s design. Boeing received an initial production order for 14 service test aircraft and 250 production bombers in May 1941, this being increased to 500 aircraft in January 1942. The B-29 featured a fuselage design with circular cross-section for strength. The need for pressurization in the cockpit area also led to the B-29 being one of very few American combat aircraft of World War II to have a stepless cockpit design, without a separate windscreen for the pilots.

Manufacturing the B-29 was a complex task that involved four main-assembly factories. Thousands of subcontractors were also involved in the project. The first prototype made its maiden flight on September 1942. The combined effects of the aircraft’s highly advanced design, challenging requirements, immense pressure for production, and hurried development caused setbacks. Unlike the unarmed first prototype, the second was fitted with a Sperry defensive armament system using remote-controlled gun turrets sighted by periscopes and first flew on December 1942, although the flight was terminated due to a serious engine fire.

On February 1943, the second prototype experienced an engine fire and crashed. Changes to the production craft came so often and so fast that, in early 1944, B-29s flew from the production lines directly to modification depots for extensive rebuilds to incorporate the latest changes. USAAF-contracted modification centers and its own air depot system struggled to handle the scope of the requirements. By the end of 1943, although almost 100 aircraft had been delivered, only 15 were airworthy. This prompted an intervention by General Hap Arnold to resolve the problem, with production personnel being sent from the factories to the modification centers to speed availability of sufficient aircraft to equip the first bomb groups in what became known as the “Battle of Kansas”. This resulted in 150 aircraft being modified in the five weeks, between March and April 1944.

The most common cause of maintenance headaches and catastrophic failures was the engines. Although the Wright R-3350 Duplex Cyclone radials later became a trustworthy workhorse in large piston-engined aircraft, early models were beset with dangerous reliability problems.

In wartime, the B-29 was capable of flight at altitudes up to 31,850 feet at speeds of up to 350 mph (true air speed)). This was its best defense because Japanese fighters could barely reach that altitude, and few could catch the B-29 even if they did attain that altitude.

The General Electric Central Fire Control system on the B-29 directed four remotely controlled turrets armed with two .50 Browning M2 machine guns each. All weapons were aimed optically, with targeting computed by analog electrical instrumentation. There were five interconnected sighting stations located in the nose and tail positions and three Plexiglas blisters in the central fuselage. Five General Electric analog computers (one dedicated to each sight) increased the weapons’ accuracy by compensating for factors such as airspeed, lead, gravity, temperature and humidity. The computers also allowed a single gunner to operate two or more turrets (including tail guns) simultaneously. The gunner in the upper position acted as fire control officer, managing the distribution of turrets among the other gunners during combat. The tail position initially had two .50 Browning machine guns and a single M2 20 mm cannon. Later aircraft had the 20 mm cannon removed, sometimes replaced by a third machine gun.

The crew would enjoy, for the first time in a bomber, full-pressurization comfort. This first-ever cabin pressure system for an Allied production bomber was developed for the B-29 by Garrett AiResearck and a long tunnel joining the forward and rear crew compartments. Crews could use the tunnel if necessary to crawl from one pressurized compartment to the other.

In early 1945, Major General Curtiss LeMay, commander of XXI Bomber Command—the Marianas-based B-29-equipped bombing force—ordered most of the defensive armament and remote-controlled sighting equipment removed from the B-29s under his command. The affected aircraft had the same reduced defensive firepower as the nuclear weapons-delivery intended Silverplate B-29 airframes and could carry greater fuel and bomb loads as a result of the change. The lighter defensive armament was made possible by a change in mission from high-altitude, daylight bombing with high explosive bombs to low-altitude night raids using incendiary bombs. As a consequence of that requirement, Bell Atlanta (BA) produced a series of 311 B-29Bs that had turrets and sighting equipment omitted, except for the tail position, which was fitted with AN/APG-15 fire-control radar. That version could also have an improved APQ-7 “Eagle” bombing-through-overcast radar fitted in an airfoil-shaped radome under the fuselage. Most of those aircraft were assigned to the 315th Bomb Wing, Northwest Field, Guam.

In September 1941, the USAAF’ plans for war against Germany and Japan proposed basing the B-29 in Egypt for operations against Germany, as British airbases were likely to be overcrowded. By the end of 1943, plans had changed, partly due to production delays, and the B-29 was dedicated to the Pacific Theater. A new plan implemented deployed the B-29 units to attack Japan from four forward bases in southern Cina, with five main bases in India, and to attack other targets in the region from China and India as needed. The XX Bomber Command, initially intended to be two combat wings of four groups each, was reduced to a single wing of four groups because of the lack of availability of aircraft, automatically limiting the effectiveness of any attacks from China.

This was an extremely costly scheme, as there was no overland connection available between India and China, and all supplies had to be flown over the Himalayas, either by transport aircraft or by B-29s themselves, with some aircraft being stripped of armor and guns and used to deliver fuel.

The solution to this problem was to capture the Mariana Islands, which would bring targets such as Tokyo, about 1,500 mi north of the Marianas within range of B-29 attacks. The Joint Chiefs of Staff agreed in December 1943 to seize the Marianas.

US forces invaded Saipan on 15 June 1944 what was secured by 9 July. Operations followed against Guam and Tinian, with all three islands secured by August.

Naval construction battalions (Seabees) began at once to construct air bases suitable for the B-29, commencing even before the end of ground fighting. In all, five major airfields were built: two on the flat island of Tinian, one on Saipan, and two on Guam. Each was large enough to eventually accommodate a bomb wing consisting of four bomb groups, giving a total of 180 B-29s per airfield. These bases could be supplied by ship and, unlike the bases in China, were not vulnerable to attack by Japanese ground forces. The bases became the launch sites for the large B-29 raids against Japan in the final year of the warand the first combat mission was launched from there on 28 October 1944, with 14 B-29s, the first attack on the Japanese capital since the Doolittle Raid in April 1942.

Boeing B-29A Superfortress “Rattle N’ Roll” showed here belonged to the 6th Bomber Group, 313th Bomb Wing, XXth USAAF, stationed at North Field, Tinian, Marianas

The most famous B-29s were the Silverplate series. These aircraft were extensively modified to carry nuclear weapons. Serious consideration was given to using the British Lancaster bomber, as this would require less modification. The most significant modification was the enlargement of the bomb bay enabling each aircraft to carry either the “Little Boy”, an enriched uranium gun-type fission weapon or “Fat Man”, a plutonium implosion-type nuclear weapon.

Little Boy was dropped on Hiroshima on 6 August 1945 by B-29 Enola Gay, flown by Colonel Paul W. Tibbets Jr and the Fat Man was dropped on Nagasaki on 9 August 1945 by B-29 Bockscar, flown by Mayor Charles W. Sweeney.

Japan surrendered to the Allies on 15 August, six days after the bombing of Nagasaki and effectively ended World War II (Ref.: 24).