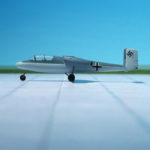

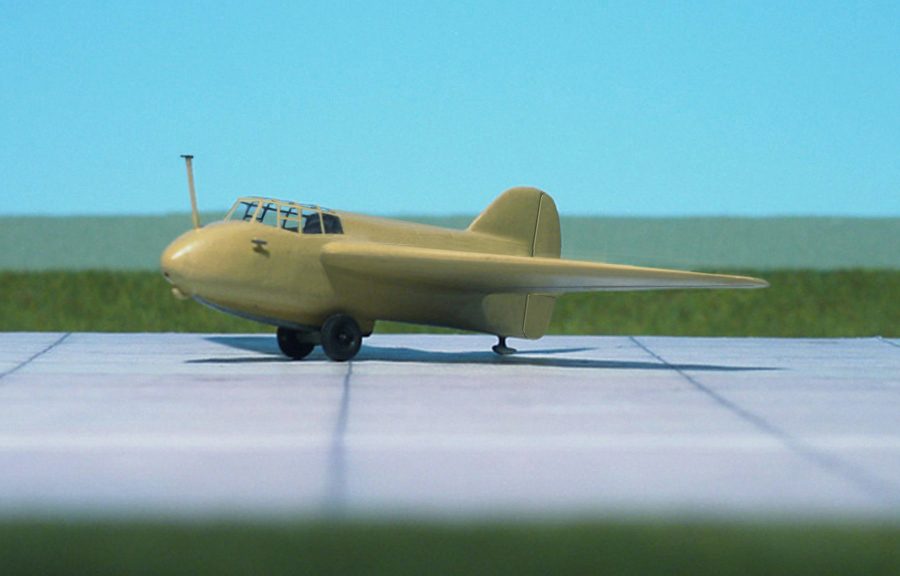

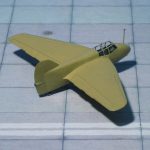

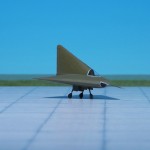

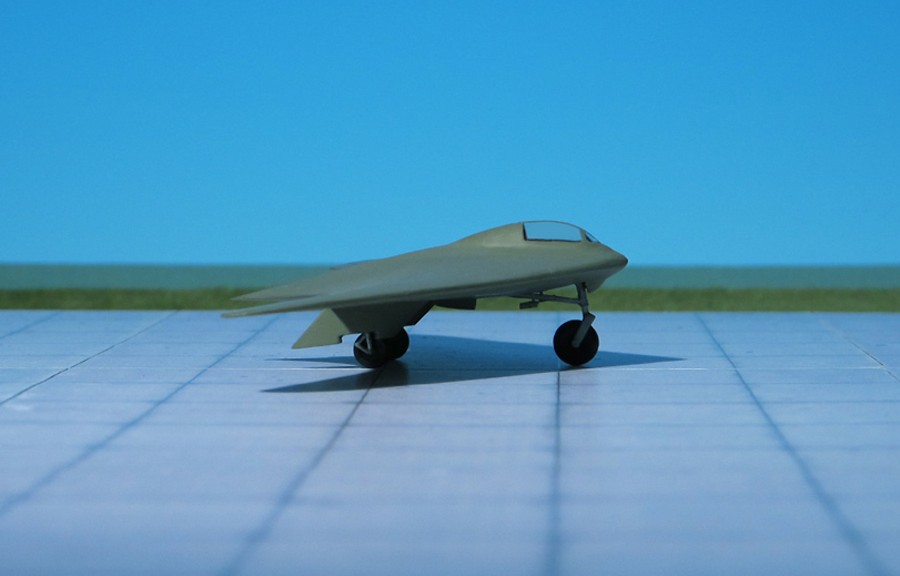

TYPE: Transport glider

ACCOMMODATION: Pilot plus 9 equipped troops 600 lb cargo

POWER PLANT: None

PERFORMANCE: Maximum towing speed 130 mph

COMMENT: The DFS 230 was a German transport glider operated by the Luftwaffe in World War II. It was developed in 1933 by the Deutsche Forschungsanstalt für Segelflug (DFS – “German Research Institute for Sailplane Flight”). The glider was the German inspiration for the British Hotspur glider and was intended for airborne assault operations.

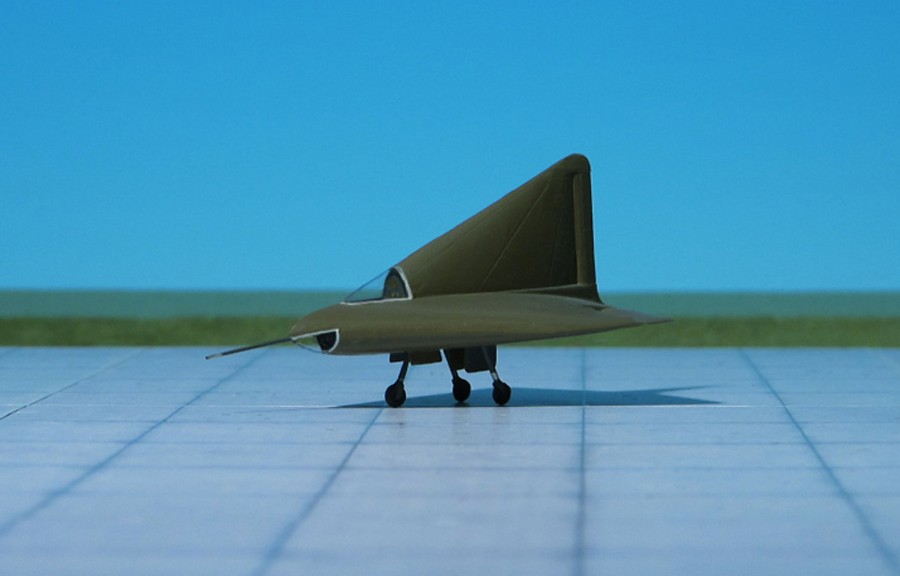

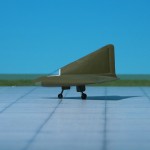

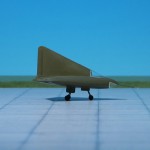

The structural design oft he DFS 230 was thoroughly conventional. The wing comprised a single mainspar at approximately one-third cord with plywood covering forward and fabric aft, the long-span ailerons with inset tabs were fabric covered, and a central keel member or boom intended to absorb the impact transmitted to it from the sprung steel skid. Provision was made for either a single or dual control, and, in addition to the pilot, accommodation was provided for nine men who were seated on the central boom, six facing forward, and four backward. Entry and exit to the cramped interior was by a single side door. The front passenger could operate its only armament, a 7,9 mm MG 15 machine gun on flexible mounting in upper decking of forward fuselage . A large loading door was provided at the rear of the cabin in the fuselage portside, and the loading of bulky items of freight was facilitated by a detachable beneath the wing at the starboard side of the fuselage. Up to 1,200 kg of freight could be loaded or 660 lb of freight in addition to the full complement of 10 men .

For take-off a two-wheel dolly was provided, this being jettisoned once the glider was airborne, it landed by means of a landing skid. The DFS 230s usually employed the Seilschlepp or cable-tow, being attached to a 131 ft cable, but for night and bad weather missions the Starrschlepp (ridgid-tow) arrangement was used. By means of a cable running along the tow rope the pilots of the tow-plane and of the freight glider were able to communicate with each other which made blind flying possible, when necessary. The towing speed of the DFS-230 was approximately 116 mph. It dropped its landing gear as soon as it was safely in the air, and landed by means of a landing skid. The DFS-230 could be towed by a Junkers Ju 52 (which could tow two with difficulty), Heinkel He 111, Junkers Ju 87, Henschel Hs 126, Messerschmitt Me 110, or a Messerschmitt Me 109.

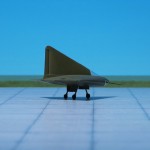

The DFS-230 had the highest glide ratio (8:1) of any World War II military glider other than the Soviet Antonov A-7. This was because it was thought that the glider had to be capable of a long approach during landing, so that it could be released a greater distance from the target so the sound of the towing aircraft did not alert the enemy.

It had been realized that glider operations were hazardous once the enemy’s ground defences had been alert, the DFS 230 providing an excellent target for small arms fire during its low, shallow landing approach. The DFS 230B was therefore fitted with an external parachute pack beneath the rear fuselage this chute being intended for deployment in the event of a rapid, diving descent necessary to avoid ground fire.

Late production version was the DFS 230C-1 with nose braking rockets for pin-point landing. A single DFS 230 was converted to an auto-gyro by replacing the wings with the 3-bladed rotor from a Focke-Achgelis Fa 223 helicopter, mounted on a pylon above the fuselage. The undercarriage was revised to include long oleo shock absorbers with a wide track for stability. Towed behind a Junkers Ju52/3M during trials, it was found that the low towing speed and low approach speed made the combination more vulnerable to attack.

The DFS 230 played significant roles in the operations at Fort Eben-Emael, the Battle of Crete, and in the rescue of Italian Dictator Benito Mussolini. It was also used in North Africa. However, it was used chiefly in supplying encircled forces on the Eastern Front. Although production ceased in 1943, it was used right up to the end of the war, for instance, supplying Berlin and Breslau until May 1945.

In total more than 1.600 aircraft had been built (Ref.: 24).