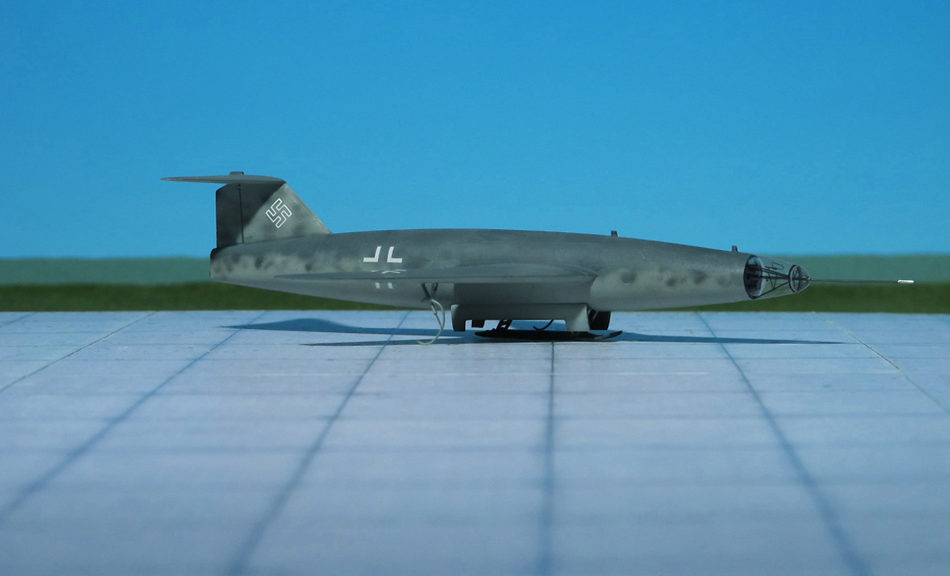

TYPE: Night fighter

ACCOMMODATION: Crew of two, Pilot and Radar operator/navigator

POWER PLANT: Two Daimler-Benz DB 603G liquid-cooled engines, rated at 1,900 hp each

PERFORMANCE: 416 mph at 22,965 ft

COMMENT: The Heinkel He 219 “Uhu” (“Eagle Owl”) was a night fighter that served with the German Luftwaffe in the later stages of WW II. A relatively sophisticated design, the He 219 possessed a variety of innovations, including Lichtenstein SN-2 advanced VHF-band intercept radar, also used on the Junkers Ju 88C and Messerschmitt Bf 110G night fighters. It was also the first operational military aircraft to be equipped with ejection seats and the first operational German World War II-era aircraft with tricycle landing gear. Had the He 219 been available in quantity, it might have had a significant effect on the strategic night bombing offensive of the Royal Air Force; however, only 294 of all models were built by the end of the war and these saw only limited service.

Development and production of the He 219 was protracted and tortuous, due to political rivalries between Josef Kammhuber, commander of the German night fighter forces, Ernst Heinkel, the manufacturer and Erhard Milch, responsible for aircraft construction in the Reichluftfahrtministerium (RLM – the German Aviation Ministry). The aircraft was also complicated and expensive to build; these factors further limited the number of aircraft produced.

When engineer R. Lusser returned to Heinkel from Messerschmitt, he began work on a new high-speed bomber project called Heinkel He P.1055. This was an advanced design with a pressurized cockpit, twin ejection seats (the first to be planned for use in any combat aircraft), tricycle landing gear — featuring a nose gear that rotated its main strut through 90° during retraction (quickly orienting the nose wheel into the required horizontal position for stowage within the nose, only at the very end of the retraction cycle) to fit flat within the forward fuselage and remotely controlled, side mounted FDSL 131 defensive gun turrets similar to those used by the Messerschmitt Me 210. Power was to be provided by two of the potentially troublesome, dual-crankcase Daimler-Benz DB 610 “power system” engines then under development, weighing on the order of about 1–1⁄2 tonnes apiece, producing 2,950 hp each, delivering excellent performance with a top speed of approximately 470 mph and a 2,500 mi range with a 2,000 kg bomb load.

The RLM rejected the design in August 1940 as too complex and risky. Lusser quickly offered four versions of the fighter with various wingspans and engine choices in order to balance performance and risk. At the same time, he offered the Heinkel He P.1056, a night fighter with four 20 mm cannon in the wings and fuselage. The RLM rejected all of these on the same grounds in 1941. Heinkel was furious and fired Lusser on the spot.

About the same time as Lusser was designing the P.1055, Kammhuber had started looking for an aircraft for his rapidly growing night fighter force. Heinkel quickly re-designed the P.1055 for this role as the Heinkel He P.1060. This design was similar in layout but somewhat smaller and powered by two of the largest displacement single-block liquid-cooled aviation engines placed in mass production in Germany, the Daimler-Benz DB 603 inverted V12 engine. As designed by Heinkel, these engines’ nacelle accommodations featured annular radiators similar to the ones on the Junkers Jumo 211-powered Junkers Ju 88A, but considerably more streamlined in appearance, and which, after later refinement to their design, were likely to have been unitized as a Heinkel-specific “Kraftei” (Power egg) engine unit-packaging design. Nearly identical-appearance nacelles, complete with matching annular radiators, were also used on the four prototypes Heinkel He 177B prototype airframes built in 1943-44, and the six ordered prototypes of Heinkel’s He 274 high-altitude strategic bombers with added turbochargers. The early DB 603 subtypes had poor altitude performance, which was a problem for Heinkel’s short-winged design, but Daimler had a new “G” subtype of the DB 603 power plant meant to produce 1,900 hp take-off power apiece under development to remedy the problem. Heinkel was sure he had a winner and sent the design off to the RLM in January 1942, while he funded the first prototype himself. The RLM again rejected the He 219, in favour of new Junkers Ju 88- and Messerschmitt Me 210-based designs.

Construction of the prototype started in February 1942 but suffered a serious setback in March, when Daimler said that the DB 603G engine would not be ready in time. Instead, they would deliver a 603A engine with a new gear ratio to the propellers, as the DB 603C with the choice of using four-blade propellers, as the similarly-powered Focke-Wulf Fw 190C high-altitude fighter prototypes were already starting to use into early 1943, with the DB 603. DB 603 engines did not arrive until August 1942 and the prototype did not fly until November 1942.

When Kammhuber saw the prototype, he was so impressed that he immediately ordered it into production over Milch’s objections. Milch – who had rejected the He 219 in January in favor of the Junkers Ju 388J was enraged.

Stability problems with the aircraft were noted but Heinkel overcame these by offering a cash prize to engineers who could correct them. Further changes were made to the armament during the development of the prototype He 219V-series. The dorsal rear defensive guns mounted atop the fuselage and firing directly rearward from a fixed, internally mounted, rear-facing dorsal “step” position, at a point just aft of the wing trailing edge, were removed due to their ineffectiveness. The forward-firing armament complement of the aircraft was increased to two Mauser MG 151/20 20 mm cannon in the wing roots, inboard of the propeller arcs to avoid the need for gun synchronizers, with four more MG 151/20 cannon mounted in the ventral fuselage tray, which had originally ended in a rearwards-facing “step” similar to and located directly under the deleted rear dorsal “step” – this rearwards-facing feature was also deleted for similar reasons.

The Heinkel He 219A-0 model featured a bulletproof shield that could be raised in the front interior cockpit, hiding the entire bottom portion of the windscreen, providing temporary pilot protection and leaving a sighting slot by which the gunsight could be aimed at a bomber. Production prototypes were then ordered as the Heinkel He 219A-0 and quickly progressed to the point where prototypes V7, V8 and V9 were handed over to operational units in June 1943 for testing.

The earlier prototypes, with four-blade propellers for their DB 603 engines (also used on the Fw 190C prototypes, with the same DB 603 engine) had blunt, compound-curvature metal nose cones also used for production-series He 219A airframes. The initial examples of these nose cones possessed cutouts for their use with the quartet of forward-projecting masts for the “Matratze” (“Mattress”) 32-dipole radar antennae on the noses of at least the first five prototypes, used with the early UHF-band “Lichtenstein” B/C or C-1 radar installation. These early He 219V-series prototype airframes also had cockpit canopies that did not smoothly taper aftwards on their upper profile, as on the later production He 219A-series airframes, but instead ended in a nearly hemispherically-shaped enclosure. The fourth prototype, He 219 V4, equipped with the earlier canopy design, had a small degree of internal metal framing within the rearmost hemispherical canopy glazing, apparently for a rear dorsal weapons mount or sighting gear for the deleted fixed “step”-mount rearwards-firing armament.

The first major production series was the Heinkel He 219A-0, although initially the pre-production series, it matured into a long running production series, due to numerous changes incorporated into the design, along with the cancellation of several planned variants. Production problems as a result of Allied bombing in March meant the A-0 did not reach Luftwaffe units until October 1943. The A-0 was usually armed with two 20 mm MG 151/20 cannon in the wing roots and up to four 20 mm or 30 mm cannon in a ventral weapons bay. The first 10–15 aircraft were delivered with the 490 MHz UHF-band FuG 212 “Lichtenstein” C-1radar with a 4 × 8-dipole element “Matratze” antenna array. 104 Heinkel He 219A-0s were built until the summer of 1944, the majority of them at EHW (Ernst Heinkel Wien) or Heinkel-Süd in Wien-Schwechat (Ref.: 24).